A GOLDEN HERITAGE AND AN ANCESTRAL TRADITION

WHOSE ESSENCE HAS HARDLY CHANGED OVER THE CENTURIES

TRADITIONAL OLIVE OIL PRODUCTION

PROCESS

The olive harvest starts around the month of October and extends until January. Our olives are carefully handpicked to avoid damaging them and to preserve their quality.

This manual technique of harvesting olives is mastered by local resources and never by modern machinery, and the result is olives and extra virgin olive oil of exceptional quality.

To ensure peak freshness and highest quality, our olive oil is extracted from our 100 % organic olives within less than 24 hours of their harvest to ensure that all of the essential antioxidants, polyphenols and micronutrients in our olive oil are retained. This process allows the oil to be extracted naturally from the olive paste, without incorporating hot water or other external inputs.

The olives are cold-pressed using a hydraulic press, which allows for the natural separation of olive oil from the paste.

During this stage, water and olive oil are separated using vertical centrifugal separators. The heavier water flows towards the outside of the rotating cylinder, while the lighter oil is collected in the center. Rigorous analytical control is conducted to verify the yield and quality of the oil according to the required standards.

The oil is temporarily stored in settling tanks, which allow the remaining micro-residues of water to be naturally removed from the oil.

Following this process and upon exiting the tanks, our extra virgin olive oil is stored in double-walled insulated stainless steel tanks and underground stacks to preserve its essential antioxidants, polyphenols, and micronutrients.

The best conditions are then put in place to preserve the oil in order to guarantee the best quality product that you can fully enjoy its aromas and benefits.

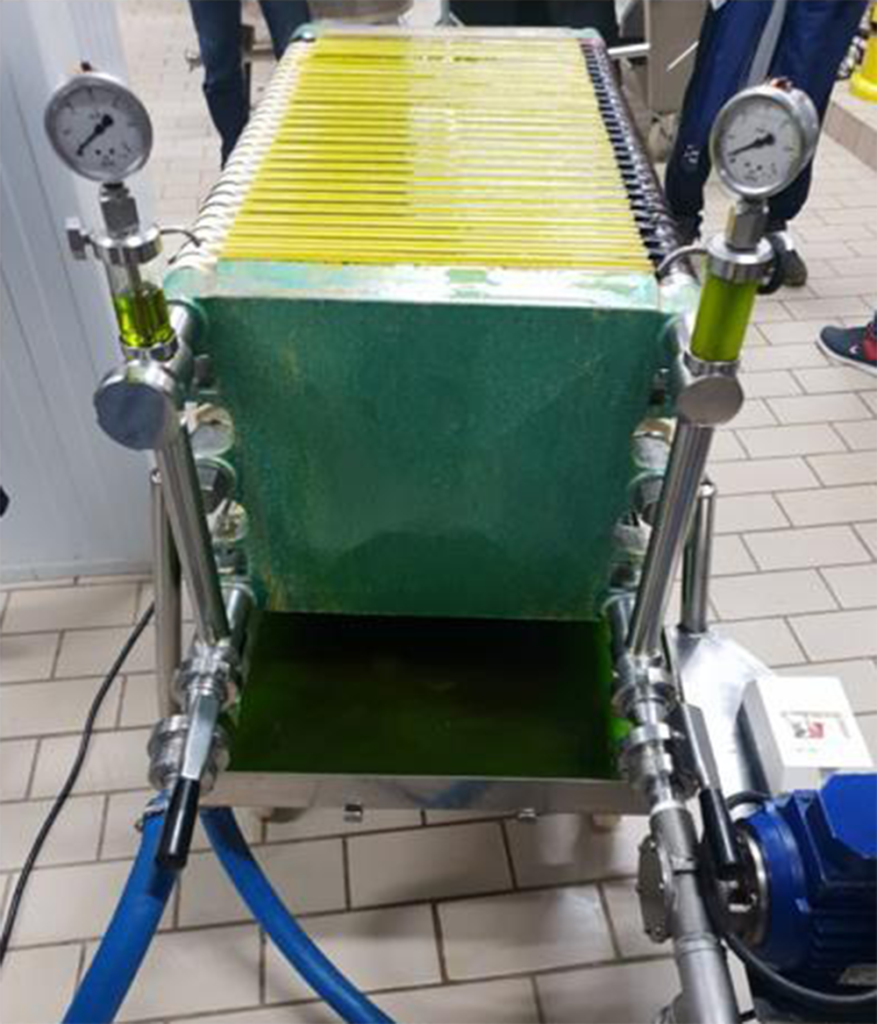

This step involves filtering the oil that was in the tank using a mechanical leaf filter. The oil is pressurized through these special paper sheets with microscopic holes and is then sent to the bottling machine.

It is in the packaging unit that olive oil tradition gives way to innovation. Indeed, the bottling of our olive oil goes through several important steps using state-of-the-art packaging lines. These machines ensure an automated, hygienic bottling process that complies with current food safety standards.

It is important to note that nowadays, there are modern manufacturing methods that use more advanced technologies to extract olive oil. However, the traditional olive oil production process remains the most appreciated method for the quality and flavor of the resulting olive oil.